Free Shipping on All Orders over $100

Every Coley Home product is crafted with care in our Claremont, North Carolina facility. Our dedicated team of over 70 skilled artisans brings passion and precision to every step of the process. By keeping production in-house, we maintain full control over quality, timelines, and the finer details—so we can deliver only the best into your home.

Your custom order is entered into our Materials Requirement System (MRS), which alerts our Manufacturing Team of all the necessary components. Thanks to our well-stocked inventory of fabrics, frames, and poly materials for our Quick Ship program, we're able to get started right away.

Fabric is placed on our state-of-the-art CAM system, and the corresponding CAD file is loaded to guide the precise cuts. Each piece is carefully inspected. For more intricate orders or those featuring multiple fabrics, our expert cutters use hand-laid paper patterns—an art form requiring precision and experience.

Cut pieces head to our Sewing Department, where our skilled sewers follow detailed specifications unique to each style. First, the body of the piece is sewn, followed by backs and cushions. French seams are added as specified for a polished finish, and raw edges are secured using a serger. Once sewing is complete, the order is ready for upholstery.

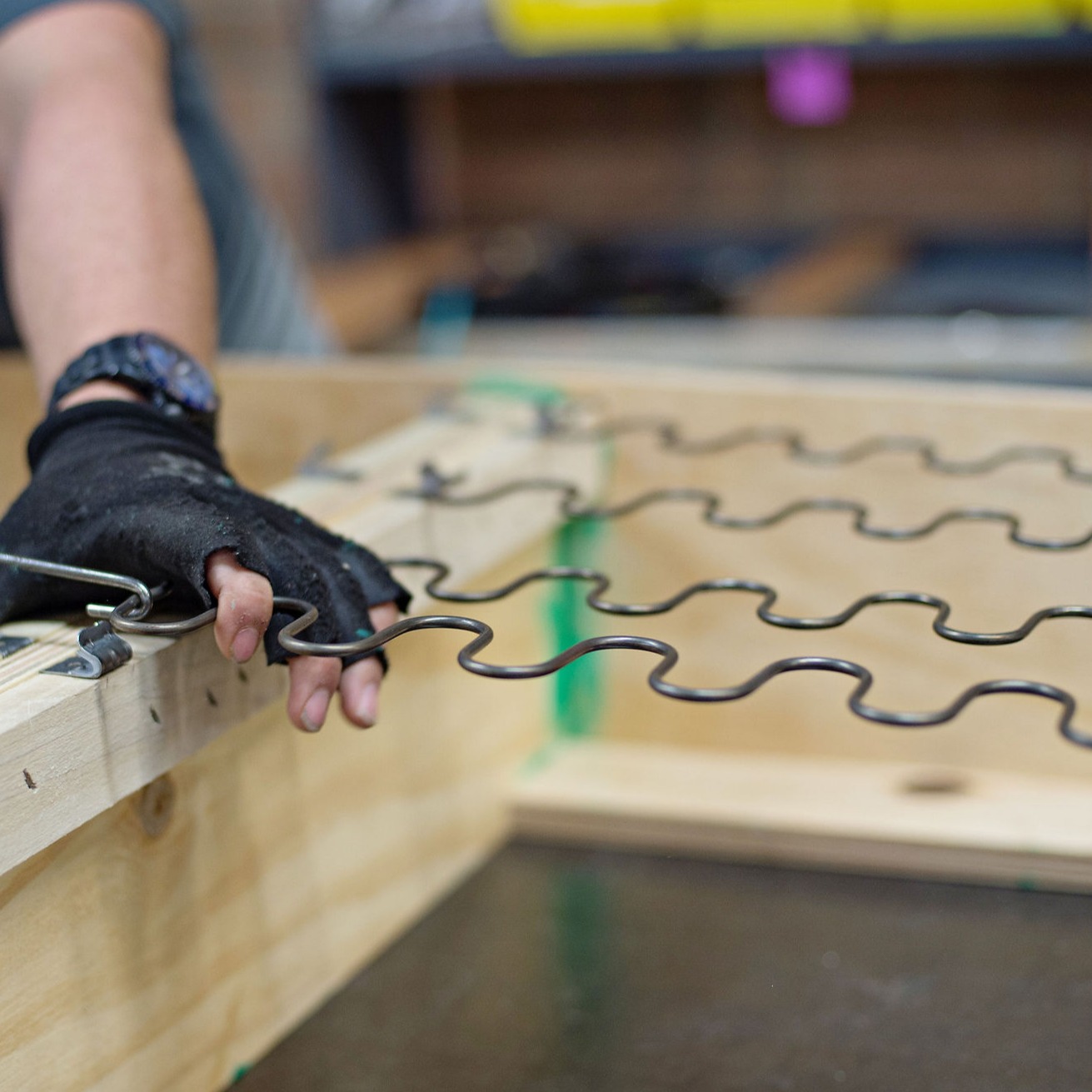

Frame components are selected and assembled using industrial-grade staples and high-strength glue. Sinuous springs are added to the seat and back as needed, and nylon webbing is applied to open frame areas for added support and longevity.

Our Insiders expertly add poly, fiber, and cotton to the arms, seats, backs, and sides. The fabric is stretched, adjusted, and stapled to ensure a flawless fit. Once upholstery is complete, the piece moves on to trimming.

Trimmers add finishing details such as welting and seamless panels (like the outside back), and attach legs or swivels where needed. Cushions and backs are filled according to your specifications.

Your piece undergoes a thorough inspection and is compared to your original order. Once it passes quality control, it’s cleaned and carefully packed. Packing includes a heavy-duty cardboard tray, a protective nylon bag, and a shrink-wrap cover for added security. Foam blocks are placed strategically to guard against any damage during transit.

Your handcrafted piece is now ready for its journey to your home. We take great pride in what we make—and we hope you love it just as much as we loved creating it for you.

At Coley Home, we’re committed to creating timeless, beautifully crafted pieces while minimizing our impact on the environment. Every decision, from materials to manufacturing, is made with care for our planet and our community.

Our furniture is made-to-order by hand, eliminating the waste associated with mass-produced, unsold inventory. Our talented team, with decades of experience in the furniture industry, takes pride in crafting high-quality pieces that are built to last.

By manufacturing everything ourselves, we retain full control over how our products are made and where our materials come from. In fact, the majority of our materials, excluding some fabrics, are sourced within a 100-mile radius of our North Carolina facility. This drastically reduces emissions and fuel consumption while supporting local suppliers and sustaining jobs in our community.

Foam is a core component of our upholstered furniture and bedding, so we prioritize sourcing it locally and responsibly. We use CertiPUR-US® certified foam combined with soy-based polyols, offering a safer, more sustainable option for your home and the environment.

Our foam is:

The wood used in our frames is responsibly harvested and finished with low-VOC coatings, reducing the presence of harmful chemicals. Once your order is placed, our in-house team begins hand-building your custom frame with precision and care. Our frames are crafted from responsibly harvested engineered hardwood, featuring interlocking glued joints and corner blocks for added durability.

We use sinuous springs made from 80% recycled metal, helping preserve natural resources and reduce the need for new raw materials.

We ship most of our products directly to your door—no middleman—further cutting down on emissions, packaging waste, and excess fuel consumption.

We ship most of our products directly to your door—no middleman—further cutting down on emissions, packaging waste, and excess fuel consumption.

At Coley Home, sustainability isn’t a trend - it’s a responsibility. We’re proud to craft pieces that are not only beautiful and built to last, but also thoughtfully made with the planet in mind.